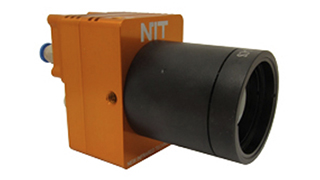

New Infrared Technologies (NIT)

超高速中赤外カメラ

New Infrared Technologies社(以下 NIT社)は、スペインはマドリードにある、1~5µm(3.7µmピーク)感度の中赤外(MWIR)センサー / カメラを製造 / 販売するメーカーです。

独自開発のPbSeの非冷却のセンサーにより、コンパクトな筐体と手ごろな価格のMWIRセンサー / カメラを実現しています。

PbSe(セレン化鉛)センサーは1~5µmの近~中赤外帯域に対応した赤外線センサーで、感度のピークは3.5~3.7µm、高速 ・ 高感度という特長があります。

水分計、放射温度計、ガス分析計、溶接モニターなどのアプリケーションに適しています。

製品ラインアップ

カスタマイズ例

- ディテクタ形状:Multielement, Linear, Imaging FPA

- 素子数:To be defined

- 素子設計:Pixel size, pitch, geometry

- 基板:Silicon, sapphire, silica, others

- パッケージング:SMD / TO-x, others

- ノンハーメチック / ハーメチック

- 冷却方法:Uncooled, 1-TEC, 2-TEC, 3-TEC

- 分光フィルタリング:Bandpass, Linear Variable Filter